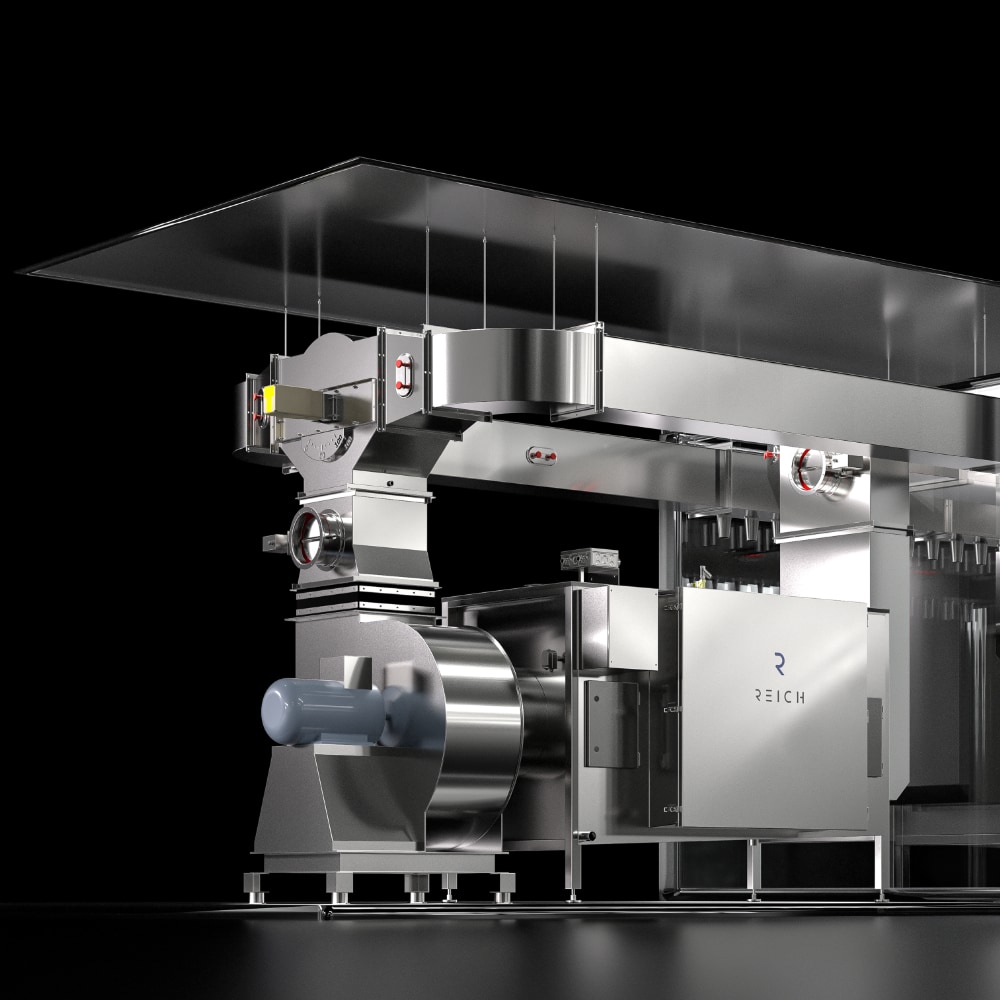

130 Years of Taste Engineering: Now With Smart Control at Your Fingertips

For over 130 years, REICH has shaped the future of thermal processing systems. From our roots in Schechingen to global leadership in food processing innovation, we’ve never stopped refining how the world treats meat, poultry, fish, cheese, plant-based foods and more. Now, we’re entering a new era. …

New EU F-Gas Regulation and Its Impact

Important Update from Alpha: New EU F-Gas Regulation and Its Impact As an agent for MAJA, Alpha would like to inform you about the upcoming changes due to the new EU F-Gas Regulation, which will come into effect on January 1, 2025. This regulation will have significant implications for manufacturers and distributors of ice makers using F-gases. From that date, MAJA, a part of Marel, will no longer manufacture or ship certain ice machines within Europe and globally. …

MAJA flake ice machines

Flake Ice Solutions for Premium Sausage Production At Carnitec, we offer top-tier flake ice machines designed to enhance sausage production. Our MAJA flake ice machines ensure hygienic and sustainable ice production, perfectly suited for cooling sausage meat. …

VDMA Reports Record Figures in Food Processing Machinery Exports

In 2023, German manufacturers of food processing and packaging machinery celebrated a notable achievement, registering an 8.6% increase in export growth, culminating in a record-breaking revenue of €9.85 billion. This surge wasn’t confined to Germany alone; it mirrored a broader, global trend that has seen the international market for these industries projected to exceed €52 billion in the same year. …

Introducing Höcker’s Versatile Smoking Trolley : Simplicity Meets Practicality

In the fast-changing field of food processing, it is crucial to be efficient and flexible. The Höcker Group, which makes custom stainless steel solutions and is located in Wallenhorst (Germany), has once more set a new standard with its inventive Höcker Smoking Trolley that addresses these requirements. This trolley includes shelves that can be adjusted for height making it possible to smoke meats, cheeses and other products while utilising space optimally as well as conserving energy. …

Innovating Tomorrow: The Pioneering Journey of Anuga FoodTec 2024

In the bustling heart of Cologne, from 19 to 22 March 2024, an unprecedented convergence of minds and technology, Anuga FoodTec 2024, is set to redefine the food and beverage industry landscape. Organized by the esteemed German Agricultural Association (DLG), this global supplier trade fair is not merely an event; it’s a crucible of innovation, sustainability, and responsibility. As the world pivots towards a more sustainable and equitable future, Anuga FoodTec 2024 emerges as a beacon of progress, guiding the food and beverage production sectors into a new era of excellence and innovation. …

REICH ATA ClimaStar’s Defrosting Excellence

In the ever-evolving landscape of the meat processing industry, the REICH ATA ClimaStar defrosting systems have carved a niche for themselves. Known for their economical and gentle defrosting processes, these systems are adept at handling everything from thinly sliced, unpackaged frozen products to thick, packaged frozen blocks, making them an indispensable part of modern food processing. …

Latvian Food Industry 2023 Outlook and 2024 Forecast

As we delve into the Latvian food industry, a sector characterised by resilience and adaptability, we uncover the key factors that shaped its trajectory in 2023 and forecast the challenges and opportunities that lie ahead in 2024. This comprehensive analysis provides investors, policymakers, and industry stakeholders with valuable insights into the market dynamics, investment trends, and strategic shifts in this vital economic sector. …

The Ultimate Craftsmanship of DarkNitro Knives: A Cut Above the Rest

Friedr. Dick, a renowned name in the world of culinary tools, presents the DarkNitro knife series – a testament to unparalleled craftsmanship. Just a glance reveals the exceptional nature of these knives, distinguished by their unique design and functionality. …